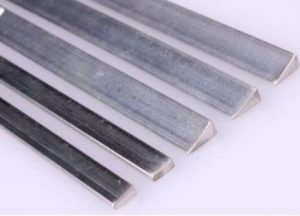

Triangle Aluminum Bar By JawaySteel

Basic Info

- Surface Finishing: as Per Required

- Alloying Ingredient: 6061

- Certification: ISO

- Polished Aluminum Profile: Chemical Polishing

- Aluminum Alloy: 1000 Series to 8000 Series

- Length: up to 5000 mm

- Width or Diameter: up to 150 mm

- Height or Diameter: up to 150 mm

- Wall Thickness: up to 10 mm

- Surface Finish: Oxidation,Powder Coating.etc.

- Packing Way: Best Suitable Packing Way

- Aluminum Temper: T3-T6

- Usage: Construction and Building

- Trademark: JawaySteel

- Transport Package: Best Suitable Packing Way

- Specification: Custom

- Origin: DaiNan, China

| Min. Order / Reference FOB Price | |

|---|---|

| 500 Kg | US $3.2/ Kg(this price is for reference only) |

| Port: | Shanghai, China |

|---|---|

| Production Capacity: | 100 Tons Per Month |

| Payment Terms: | L/C, T/T, D/P, Western Union, Money Gram |

| Type: | Construction |

|---|---|

| Shape: | Multi Kinds |

| Grade: | 6000 Series |

| Temper: | T3-T8 |

| Window & Door Aluminium Profile: | 60 Series |

| Alloy: | Alloy |

Product Description

| 1. Aluminum alloy number | ||||||||||||||

| No. | Aluminum Alloy Number | |||||||||||||

| 1.1 | 1100,1060,1070,2024,3003,5A02,6061,6063,etc. | |||||||||||||

| 2. Product size and tolerance | ||||||||||||||

| No. | Specification | Size | Tolerance | |||||||||||

| 2.1 | Length (mm) | Up to 5000 | ±1 | |||||||||||

| 2.2 | Width (mm) | Up to 150 | ±0.08 | |||||||||||

| 2.3 | Height (mm) | Up to 150 | ±0.08 | |||||||||||

| 2.4 | Thickness (mm) | Up to 10 | ±0.02 | |||||||||||

| 3. Chemical composition for some typical alloys | ||||||||||||||

| No. | Internal Alloy Number |

AA number | Chemical Composition (%) | |||||||||||

| Si | Fe | Cu | Mn | Mg | Zn | Ti | Zr | Bi | Others | Al | ||||

| Each | Total | |||||||||||||

| 3.1 | 1060 | 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | 99.6 | |||

| 3.2 | 1070 | 1070 | 0.2 | 0.25 | 0.04 | 0.03 | 0.03 | 0.04 | 0.03 | 0.03 | 99.7 | |||

| 3.3 | 1100 | 1100 | 0.95 | 0.05-0.2 | 0.05 | 0.1 | 0.05 | 0.15 | RE | |||||

| 3.4 | 3003 | 3003 | 0.6 | 0.7 | 0.05-0.2 | 1-1.5 | 0.05 | 0.1 | 0.05 | 0.15 | RE | |||

| 3.5 | 3005 | 3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.25 | Cr 0.1 | 0.05 | 0.15 | RE | ||

| 3.6 | 4004 | 4004 | 9.0-10.5 | 0.8 | 0.25 | 0.1 | 1.0-2.0 | 0.2 | 0.05 | 0.15 | RE | |||

| 3.7 | 4045 | 4045 | 9.0-11.0 | 0.8 | 0.3 | 0.05 | 0.05 | 0.1 | 0.05 | 0.15 | RE | |||

| 3.8 | 4047 | 4047 | 11.0-13.0 | 0.8 | 0.3 | 0.15 | 0.05 | 0.2 | 0.05 | 0.15 | RE | |||

| 3.9 | 4104 | 4104 | 9.0-10.5 | 0.8 | 0.25 | 0.1 | 1.0-2.0 | 0.2 | 0.05-0.2 | 0.05 | 0.15 | RE | ||

| 3.10 | 4343 | 4343 | 6.8-8.2 | 0.8 | 0.25 | 0.1 | 0.05 | 0.2 | 0.05 | 0.15 | RE | |||

| 3.11 | 4343A | 4343A | 6.8-8.2 | 0.6 | 0.1 | 0.1 | 0.02 | 0.1 | 0.05 | 0.15 | RE | |||

| 3.12 | 6060 | 6060 | 0.3-0.6 | 0.1-0.3 | 0.1 | 0.1 | 0.35-0.6 | 0.15 | 0.1 | Cr 0.05 | 0.05 | 0.15 | RE | |

| 3.13 | 6061 | 6061 | 0.4-0.8 | 0.7 | 0.15-0.4 | 0.15 | 0.8-1.2 | 0.25 | 0.15 | Cr 0.04-0.35 | 0.05 | 0.5 | RE | |

| 3.14 | 6063 | 6063 | 0.2-0.6 | 0.35 | 0.1 | 0.1 | 0.45-0.9 | 0.1 | 0.1 | Cr 0.1 | 0.05 | 0.15 | RE | |

| 3.15 | 6A02 | 6A02 | 0.5-1.2 | 0.5 | 0.2-0.6 | 0.1-0.35 | 0.45-0.9 | 0.2 | 0.15 | 0.05 | 0.15 | RE | ||

| 3.16 | 7072 | 7072 | 0.7 | 0.1 | 0.1 | 0.1 | 0.1 | 0.8-1.3 | 0.05 | 0.15 | RE | |||

| 4. Mechanical properties for some typical alloys | ||||||||||||||

| No. | Alloy number | Thick. (mm) |

Temper | Yield Strength Rp0.2(Mpa). Min |

Tensile Strength Rm (Mpa) |

Elongation (%) A50,Min |

||||||||

| 4.1 | 3003 | 0.08-0.15 | O | 35 | 95-135 | 8 | ||||||||

| 4.2 | 3003 | 0.16-0.35 | O | 35 | 95-135 | 10 | ||||||||

| 4.3 | 3003 | 0.15-0.3 | H12 | 90 | 120-175 | 0.5 | ||||||||

| 4.4 | 3003 | 0.06-0.08 | H14 | 125 | 145-185 | 0.5 | ||||||||

| 4.5 | 3003 | 0.081-0.3 | H14 | 125 | 145-200 | 0.5 | ||||||||

| 4.6 | 3003 | 0.06-0.16 | H16 | 160 | 165-205 | 0.5 | ||||||||

| 4.7 | 3003 | 0.2-0.3 | H24 | 125 | 145-205 | 6 | ||||||||

| 4.8 | 3003-1 | 0.35-3.0 | O | 35 | 95-135 | 20 | ||||||||

| 4.9 | 3003-1 | 0.40-3.0 | H14 | 125 | 145-185 | 3 | ||||||||

| 4.10 | 3003-1 | 1.0-3.0 | H24 | 125 | 145-185 | 10 | ||||||||

| 4.11 | 6A02 | 0.8-4.5 | O | ≤85 | ≤150 | 20 | ||||||||

| 4.12 | 6060 | 0.8-4.5 | O | ≤85 | ≤150 | 20 | ||||||||

| 4.13 | 6063 | 0.8-4.5 | O | ≤85 | ≤150 | 20 | ||||||||

| 4.14 | 4343 | 0.07-3.0 | O | 35 | 95-150 | 8 | ||||||||

| 4.15 | 4343 | 0.07-3.0 | H14 | 120 | 140-200 | 0.5 | ||||||||

| 4.16 | 4045 | 0.07-3.0 | O | 35 | 95-150 | 8 | ||||||||

| 4.17 | 4045 | 0.07-3.0 | H14 | 120 | 140-200 | 0.5 | ||||||||

| 4.18 | 4104 | 0.07-3.0 | O | 35 | 95-150 | 8 | ||||||||

| 4.19 | 4104 | 0.07-3.0 | H14 | 120 | 140-200 | 0.5 | ||||||||

| 4.20 | 4A13 | 0.07-3.0 | O | 35 | 95-150 | 8 | ||||||||

| 4.21 | 4A13 | 0.07-3.0 | H14 | 120 | 140-200 | 0.5 | ||||||||

| 4.22 | 4047 | 0.07-3.0 | O | 35 | 95-150 | 8 | ||||||||

| 4.23 | 4047 | 0.07-3.0 | H14 | 120 | 140-200 | 0.5 | ||||||||

| 4.24 | 3003 | 0.25-0.35 | H24 | 130 | 155-205 | 6 | ||||||||

| 4.25 | 3003 | 0.1-0.2 | H14 | 125 | 145-185 | 1 | ||||||||

| 4.26 | 3003 | 0.1-0.3 | O | 35 | 95-135 | 10 | ||||||||

| 4.27 | 3003 | 0.3-0.8 | H14 | 125 | 145-185 | 2 | ||||||||

| 4.28 | 3003 | 0.8-2.5 | H14 | 125 | 145-185 | 4 | ||||||||

| 4.29 | 3003 | 0.5-1.6 | O | 35 | 145-185 | 20 | ||||||||

| 4.30 | 3003-1 | 0.3-1.8 | O | 35 | 95-135 | 20 | ||||||||

| 4.31 | 3003-1 | 0.5-4.0 | O | 35 | 95-135 | 25 | ||||||||

| 4.32 | 3005 Mod | 0.25-0.6 | H24 | 150 | 185-235 | 8 | ||||||||

| 4.33 | 6060 | 0.8-4.5 | O | ≤85 | ≤150 | 20 | ||||||||

| 4.34 | 6063 | 0.8-4.5 | O | ≤85 | ≤150 | 20 | ||||||||

| 4.35 | 3005 | 0.8-4.5 | O | 40 | 80-120 | 20 | ||||||||

| 4.36 | 3005 | 0.6-4.5 | H22 | 110 | 145-195 | 15 | ||||||||

| 4.37 | 1100 | 0.2-0.3 | H24 | 90 | 115-155 | 3 | ||||||||

| 4.38 | 6A02 | 1.0-5.0 | O | ≤85 | ≤150 | 20 | ||||||||

| 5. Surface finish and other properties | ||||||||||||||

| No. | Item | Description | ||||||||||||

| 5.1 | Surface finish | Original, painting,powder coating, zinc plating, etc. | ||||||||||||

| 6. Packing,Shipping and others | ||||||||||||||

| No. | Item | Description | ||||||||||||

| 6.1 | Packing | To be packed in wooden boxes | ||||||||||||

| 6.2 | Marking | Each box to be legibly marked with the name of the manufacturer or supplier, the alloy designation of material,condition,dimensions and weight | ||||||||||||

| 6.3 | Shipping tools | Ship goods by van to departune port then by sea to desitination port | ||||||||||||

| 6.4 | Quantity variation | ±10% variation with order quantity shall be acceptable | ||||||||||||