Things to watch out for when cutting a stainless steel rod with a laser?

The stainless steel laser cutting machine is a classification in the metal laser cutting machine. It is specially designed for stainless steel. The energy released by the laser beam on the surface of the steel plate melts and evaporates the stainless steel.

Stainless steel is used in a wide range of applications, such as kitchen equipment, general tensile materials, gas stoves, refrigerators, electrical appliances, washing machines, dryer microwave ovens, electronic components, steel pipes, decorative pipes, structural pipes, pipes, building materials, Re-grinding, elevators, interior and exterior decorative materials, windows, door materials, chemical equipment, heat exchangers, boilers, tanks, etc., so that stainless steel is widely used.

Mechanism of laser cutting of stainless steel

Stainless steel sheet laser cutting machine occupies a large proportion in industrial production. The main areas of stainless steel and low carbon copper are different in composition, and the cutting mechanism is also different. Stainless steel containing 1% to 20% chromium tends to destroy the oxidation process.

The iron in the stainless steel will be exothermicly reacted with oxygen during cutting. The oxidation of chromium has the property of preventing oxygen from entering the inside of the molten material, and the amount of oxygen entering the molten layer is reduced. The oxidation of the molten layer is incomplete, the reaction is reduced, and the cutting speed is increased. reduce.

Compared with low carbon steel, stainless steel cutting requires higher laser power and oxygen pressure, while stainless steel cutting achieves a satisfactory cutting effect, but it is difficult to obtain a completely non-stick slag.

The use of inert gas as an auxiliary gas to cut stainless steel can obtain non-oxidized trimming, which is directly used for welding, but its cutting speed is reduced by about 10% compared with oxygen as an auxiliary gas.

Things to watch out for when cutting a stainless steel rod with a laser

Stainless steel laser cutting quality control

Stainless steel laser cutting is higher in cost than wire cutting. The precision is not as good as wire cutting, but the speed is twice that of wire cutting. It can realize large-volume production, and can process non-metallic materials after cutting to realize intelligent processing. One machine replaces multiple stages and becomes the core of processing equipment.

It can be seen that stainless steel laser cutting is a fast and effective processing method, but the control of cutting quality is particularly important.

When laser-cut mirror stainless steel, in order to prevent serious burns on the sheet, you need to attach a laser film! Although there is membrane protection, there will be a little burn on the edges.

At this time, it is necessary to strictly control the laser cutting process parameters during the processing to maintain the good corrosion resistance of such materials. The most important process parameters that affect the quality of stainless steel cutting are cutting speed, laser power, oxygen pressure and focus.

In addition, the stainless steel products in many industries require a relatively high surface smoothness. What about the burr change in the stainless steel laser cutting laser cutting machine?

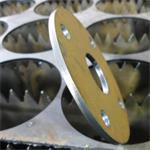

The burr of stainless steel laser cutting is generally the cutting head of the cutting head. First of all, this factor should be investigated. If the cutting nozzle cannot be solved, it is necessary to check whether the movement of the laser cutting machine guide rail is stable.