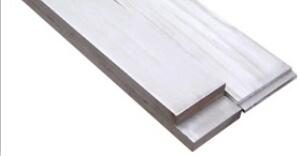

Stainless Steel Flat Bar Basic Information

Stainless steel flat steel is a rectangular and slightly pure steel.

There are cold drawn polished stainless steel flat bar and hot rolled acid white sandblasted stainless steel flat bar.

Stainless steel flat steel can be composed of various force-receiving members according to the different needs of the structure, and can also be used as a connecting member between the members.

Widely used in a variety of building structures and engineering structures, such as beams, bridges, transmission towers, lifting and transport machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves.

The raw material billet for producing stainless steel flat steel is a low carbon square billet, and the finished stainless steel flat steel is delivered for hot rolling forming, cold rolling or hot rolling.

Stainless Steel Flat Bar Polished

Application range

Stainless steel has been widely used due to its high corrosion resistance and decorative properties, especially in medical appliances, food industry appliances, tableware, kitchen utensils, etc.

Stainless steel appliances should be corrosion-resistant, bright and clean, and the surface of the appliance should not be attached with substances that are toxic to the human body.

Therefore, the requirement for the surface treatment of such tools is to completely remove the harmful substances on the surface.

Oxidation cause

Stainless steel will form a black or gray scale on the surface after hot working, machining or placement for a certain period of time.

Its main components are Cr2O3, NiO and very insoluble FeO and Cr2O3. Their existence affects the appearance quality on the one hand and the product performance on the other hand.

Therefore, appropriate measures should be taken to remove them.

As a mature surface treatment method, stainless steel polishing has been widely used, and polishing can further improve the corrosion resistance and brightening effect of stainless steel.

Polishing classification

Mechanical polishing:

Grinding wheel polishing

Sandblasting

Grinding and polishing

Extrusion polishing

Electrochemical polishing and polishing:

Chemical polishing

Composite grinding and polishing:

Combination of mechanical and chemical methods

For different metal materials, different applications, different requirements for the surface of the metal workpiece, must be combined with different grinding methods or several grinding methods in order to make the workpiece meet the requirements of use.

(Let’s take it down in detail:Chemical polishing、Electrolytic polishing)

Chemical polishing

Chemical polishing is a commonly used surface treatment process for stainless steel.

Compared with the electrochemical polishing process, the biggest advantage is that it does not require a DC power supply and special fixtures, and can polish complex-shaped parts with high productivity.

In terms of functionality, in addition to physical and chemical cleanliness, chemical polishing removes the mechanical damage and stress layers on the stainless steel surface, resulting in a mechanically clean surface that helps prevent localized corrosion of the part. Mechanical strength and extended part life.

Since the patent on stainless steel chemical polishing in the early 1940s, many formulations have been made public so far, but people still find it difficult to use in practical applications.

Because of the wide variety of stainless steels, different grades of stainless steel have different corrosion laws, it is impossible to use the same solution, so there are many types of stainless steel chemical polishing solutions.

The basic composition of the chemical polishing solution includes an etchant, an oxidant, and water.

The etchant is the main component, and if the stainless steel is dissolved in the solution, polishing cannot be performed. Oxidants and additives inhibit the process, allowing the reaction to proceed in a direction that favors polishing.

Water regulates the concentration of the solution to facilitate the diffusion of the reaction product. Whether stainless steel chemical polishing can proceed smoothly depends on the reasonable combination of the above ingredients.

Electrolytic polishing

Stainless steel electropolishing is to hang the stainless steel product on the anode and perform anodic electrolysis processing in the electrolytic polishing liquid.

Electropolishing is a special anode process. During the entire anodic electropolishing process, two contradictory processes are simultaneously carried out on the surface of the stainless steel product, namely the continuous formation and dissolution of the oxide film on the metal surface.

However, the conditions for the chemical film formation of the convex portion and the concave portion of the stainless steel product to enter the passive state are different, and the concentration of the metal salt in the anode region is continuously increased due to the dissolution of the anode, and a high resistivity thickness is formed on the surface of the stainless steel product. Mucosal layer.

The thickness of the thick mucosa on the surface of the product is not the same, and the microscopic surface current of the anode is unevenly distributed.

The current density of the micro-bumps is large, and the dissolution is faster, so that the surface burrs or micro-protrusions of the product are preferentially dissolved to achieve leveling; the current density at the concave ridge is small, and the dissolution is slow.

Due to the different current density distribution, the surface of the product is continuously filmed and dissolved at different rates.

The anode surface is simultaneously subjected to two opposite processes, film formation and dissolution, and the passivation film is continuously formed and dissolved, so that the surface of the stainless steel product is leveled to achieve a highly smooth and glossy appearance, which satisfies the purpose of polishing the surface of the stainless steel product.

Polishing brightness level

Visual inspection, the brightness of the polished part surface is divided into 5 levels:

Level 1: The surface has a white oxide film with no brightness;

Level 2: slightly bright, can’t see the outline;

Level 3: good brightness, can see the outline;

Level 4: The surface is bright, and the outline is clearly seen (corresponding to the surface quality of electrochemical polishing);

Level 5: Mirror-like light.

One of the surface treatment methods of stainless steel flat steel produced by JawaySteel – polishing

Surface:

Pickled,Black,Polishing etc.

Grade and Quality:

200 series:201, 202,

300 series:303,304,304L.316.316L,321,

400 series: 430,431 410,416,420,etc

Standard:

ASTM A484,A246,A582,GB704,GB5215

Size:

Length tolerance of flat bar in cut-length or multiple length should be in accordance with

Length≤4m………………….0~+30mm

Length>4m—6mm…………. 0~+50mm

Length>6m…………………. 0~+70mm