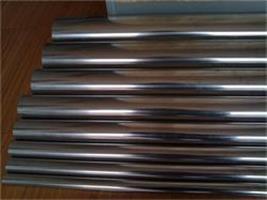

Stainless steel bar specification summary:

200 stainless steel bar – chrome-nickel-manganese austenitic stainless steel

300 stainless steel bar – chrome-nickel austenitic stainless steel

301 stainless steel bar – good ductility for molding products. It can also be hardened by machine speed. Good weldability. Wear resistance and fatigue strength are better than 304 stainless steel.

302 stainless steel bar – corrosion resistance

304 is stronger because of its relatively high carbon content

303 stainless steel bar – it is processed by adding a small amount of sulfur and phosphorus.

304 stainless steel bar – 18/8 stainless steel. The GB grade is 0Cr18Ni9.

309 stainless steel bar – better temperature resistance than 304.

316 stainless steel bar – Following 304, the second widely used steel grade, mainly used in the food industry and surgical equipment, adds molybdenum to give it a special structure that resists corrosion. It is also used as “ship steel” because it has better resistance to chloride corrosion than 304. SS316 is commonly used in nuclear fuel recovery units. 18/10 grade stainless steels are also typically compliant with this application grade model 321 stainless steel rod—except for the addition of titanium to reduce the risk of weld rust in the material.

400 stainless steel bar – ferrite and martensitic stainless steel

408 stainless steel bar – good heat resistance, weak corrosion resistance, 11% Cr, 8% Ni.

409 stainless steel bar – cheap model (English and American), usually used as a car exhaust pipe, is a ferritic stainless steel (chrome steel).

410 stainless steel bar – martensite (high strength chrome steel), good wear resistance and poor corrosion resistance.

416 stainless steel bar – the addition of sulfur improves the material’s processing properties.

420 stainless steel bar – “cutting grade” martensitic steel, similar to early stainless steel such as Brinell high chromium steel. Also used for surgical knives, it can be done very brightly.

430 stainless steel bar – ferritic stainless steel, for decoration, for example for car accessories. Good formability, but poor temperature resistance and corrosion resistance.

440 stainless steel bar – high-strength cutting tool steel, slightly higher in carbon content, can obtain higher yield strength after proper heat treatment, hardness can reach 58HRC, and it is among the hard stainless steel.

A common application example is the “razor blade.”

There are three commonly used models: 440A, 440B, 440C, and 440F (easy processing type).

500 stainless steelbar – heat resistant chrome alloy steel.

600 stainless steel – martensitic precipitation hardening stainless steel.

630 stainless steel rod – commonly used precipitation hardening stainless steel model, usually also called 17-4; 17%Cr, 4% Ni