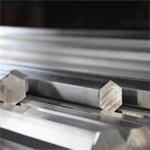

Stainless Steel Hexagon Bar

Grade and Quality:

200 series:201, Y201Cu,202,

300 series:303,304,304L,310,316.316L,321,

400 series: 410,420 ,416,430,430F,431etc

Standard:

ASTM A276,A581,A582,GB705,GB/T905

Size and Diameter:

The A/F range of our hexagon bar is S2.5~S5mm(cold rolled)

S5mm~S50mm(cold drawn),S50mm~S180mm(Milling)

Normal Length is 2000mm—6000mm

Tolerance of cut-length or multiple length is 0-+50mm if the hexagon bar was used for automatical cutting rod, When size is 7~20mm,max bending is 2mm/m; When the size is≥25mm,max wrap is 1mm/m.

Application and Usage:

Stainless steel Hexagon bar(Round bar, hexagon bar, square bar) widely used in the areas such as Fasteners, Chains, Kitchen and Sanitary wares, Furniture handles, Handrails, Electroplating ,Foods, Electron, Petroleum, Construction and decoration etc. Products have a high strength after cold working. Decoration materials and outdoor publicity billboard. Used for the products which have the anti-Stress Corrosion requirements. Electron products, table-wares, Bolts, Nuts, Screen Mesh, Cumbustors and so on.

Packing:

Full wrap by plastic packing-cloth or as per customer requirement.

Jawaysteel Corporation is one of the biggest manufacturers and producers for stainless steel bars.We can supply various sizes of stainless steel bars on high quality but factory supply pricing at most competitive rate.

Detailed introduction

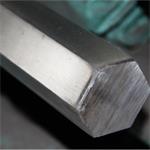

Hexagonal bars are hexagonal, solid long strips of stainless steel. Due to the characteristics of stainless steel hexagonal rods, they are widely used in marine, chemical, and construction applications.

Hexagon bar specification:H2-H90mm

Accuracy:±0.01mm

Special feature:Brightness is very good

Characteristic:

1, stainless steel hexagonal bar with high dimensional accuracy, up to ±0.01mm; size specifications: hexagonal bar specifications: H2-H90mm;

2, stainless steel hexagonal bar surface quality is excellent, light brightness is very good;

3. Stainless steel hexagonal rod has strong corrosion resistance, tensile strength and high fatigue resistance;

4. The stainless steel hexagonal rod has stable chemical composition, pure steel and low inclusion content;

Common material:

1.316L stainless steel hexagonal rod Performance: corrosion resistance, high temperature resistance, good welding performance.

2.316 stainless steel hexagonal rod performance: containing molybdenum and low carbon content, the anti-pitting ability in the marine and chemical industrial environment is much better than 304 stainless steel, after welding or after eliminating stress, its resistance to intergranular corrosion is excellent. Good corrosion resistance can also be maintained without heat treatment.

3.304L stainless steel hexagonal rod Performance: 304L stainless steel is a variant of 304 stainless steel with low carbon content, used in applications where welding is required. The lower carbon content minimizes the precipitation of carbides in the heat affected zone near the weld, which may result in intergranular corrosion (weld erosion) in certain environments.

4.304 stainless steel hexagonal bar performance: 304 is a versatile stainless steel material, anti-rust performance is stronger than the 200 series of stainless steel materials. High temperature resistance is also good, can be as high as 1000-1200 degrees. It has excellent stainless corrosion resistance and good resistance to intergranular corrosion. In addition, the 304 stainless steel material concentration ≤ 65% of the boiling temperature below the boiling temperature, has a strong corrosion resistance. It also has good corrosion resistance to alkaline solutions and most organic and inorganic acids.

Application prospects:

Stainless steel hex bars are mainly used for fasteners – stainless steel hex bolts, stainless steel hex socket head cap screws (cup head), stainless steel hex socket end set screws (concave end machine), stainless steel hex flat end set screws ( Flat end machine meter), stainless steel hexagon socket tip set screw (tip machine meter), stainless steel hexagon socket end set screw (column end machine meter), stainless steel countersunk head socket head cap screw (flat cup), stainless steel semi-circular head socket head cap screw (round cup).

The application prospects of stainless steel hexagonal rods are widely used in the fields of auto parts, elevators, kitchen equipment, pressure vessels, etc., and are consistently accepted by users. The key to application in future development is environmental protection and long life.

Regarding environmental protection, first of all, from the viewpoint of atmospheric environmental protection, the demand for high-temperature garbage incinerators, LNG power generation devices, and high-efficiency power generation devices using coal for suppressing the occurrence of dioxin will increase. With regard to long life, the use of stainless steel is increasing in existing bridges, highways, tunnels and other facilities in Europe, and it is expected that this trend will spread all over the world. In addition, the life expectancy of Japanese residential buildings is particularly short 20-30 years, and waste disposal has become a major problem. Buildings with a life expectancy of 100 years have recently emerged, and the demand for materials with excellent durability will increase.

304 stainless steel hexagonal bar

304 stainless steel is a versatile stainless steel material with stronger rust resistance than the 200 series stainless steel. High temperature resistance is also good, can be as high as 1000-1200 degrees. 304 stainless steel has excellent stainless corrosion resistance and good resistance to intergranular corrosion. Shanghai Pohang Stainless Steel Co., Ltd. obtained in the experiment: the nitric acid with boiling temperature below ≤65% of 304 stainless steel material has strong corrosion resistance. It also has good corrosion resistance to alkaline solutions and most organic and inorganic acids.

Dimensions:H2-H90mm

304 stainless steel grade: 0Cr18Ni9 (0Cr19Ni9);

Chemical composition % C: ≤ 0.07 , Si : ≤ 1.0 , Mn : ≤ 2.0 , Cr : 17.0 to 19.0 , Ni : 8.0 to 11.0 , S : ≤ 0.03 , P : ≤ 0.035 .