Stainless Steel H Beam Bar

Grade:

201 202 301 302 303 304 304L 310 316 316L 321 410 430 2520 etc.

Standard:

AISI ASTM JIS GB BS

Size:

Size:H:60mm-140mm, :B37mm-60mm, D:4.5mm-8mm

Surface:

Bright ,pickled or polishing

Application:

Stainless steel H beam bars which manufactured by Jawaysteel can used in food processing equipment, particularly in beer brewing, milk processing & wine making.Kitchen benches, sinks, troughs, equipment and appliances.Architectural panelling, railings & trim.Chemical containers, including for transportHeat Exchangers.Woven or welded screens for mining, quarrying & water filtration. Threaded fasteners.

Packing:

Export standard packing then put in container or as per customer requirement.

Jawaysteel Corporation is one of the biggest manufacturers and producers for stainless steel bars.We can supply various sizes of stainless steel bars on high quality but factory supply pricing at most competitive rate.

Detailed introduction

Stainless Steel H Beam Bar Overview

Stainless steel H beam bar is a long strip of steel with an I-shaped cross section. Stainless steel I-beam is widely used in various building structures, bridges, vehicles, brackets, machinery, etc.

Classification:

Stainless steel H beam bar is divided into ordinary I-beam and light I-beam.

Specification:

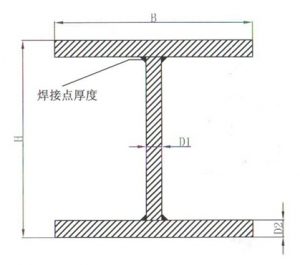

The stainless steel H beam bar model is expressed in Arabic numerals in millimeters. The web, flange thickness, web thickness and flange width are different. The waist height (h) × leg width (b) × waist thickness (d1) × Millimeter thickness of the flange (d2), such as “Stainless steel H beam bar250*120*8*10”, which means that the waist height is 250 mm, the leg width is 120 mm, the waist thickness is 8 mm, and the flange thickness is 10 mm Stainless steel H beam bar.

For the weight calculation calculation method of stainless steel welded Stainless steel H beam bar, it is possible to select the combination of the weights of the three plates constituting the I-beam. The calculation formula of the board is: length × width × thickness × density (generally 7.93g / cubic centimeter).

Artwork:

Stainless steel H beam bar and other stainless steel products are used in a wide range of applications. Many applications are exposed to the air. Like many materials used in the atmosphere, the Stainless steel H beam bar is dirty. In addition, sometimes when people store stainless steel products outside, it is easy to soil the material, so it is necessary to clean up after the dirty.

Take the stainless steel sheet as an example: the same strip can be cleaned by the effect of rain washing by placing it directly in the atmosphere and placing it in a shed. The effect of manual rinsing is determined by manually scrubbing the right side of each slat every six months with a sponge dipped in soapy water. As a result, it was found that dust and deposition on the surface by rain washing and manual scrubbing had a good effect on the surface condition as compared with the slats placed in the shed and not washed. It has also been found that the condition of the surface finish is also affected, and the smooth slats are better than the rough slats. The interval between washes is affected by a number of factors, the main influencing factors being the required aesthetic criteria. Although many stainless steel curtain walls are only rinsed while the glass is being wiped, in general, stainless steel for the exterior is scrubbed twice a year.

The timely maintenance and cleaning of Stainless steel H beam bar will have a great impact on the actual application effect. Therefore, it is recommended that customers add one more step in the storage and application process of stainless steel I-beam, which is to regularly check the pollution status and clean up in time. .